Image Source: PickPik

Businesses, researchers, and scientists must improve their processes and products continuously. One powerful tool that has revolutionized the field of experimentation is the Design of Experiments (DOE). This statistical approach allows individuals to optimize their experiments efficiently and effectively, leading to accurate and precise results.

This comprehensive guide will delve into the world of DOE and explore how it can be harnessed for modern experimentation. From understanding the fundamental concepts to practical applications, we aim to equip you with the knowledge and skills to implement DOE in your projects successfully.

Four Enduring Principles of DOE

The Design of Experiments (DOE) foundation is built upon four enduring principles introduced by Ronald Fisher in 1926. Each principle plays a crucial role in the effectiveness and reliability of experimental results. Let’s explore these principles in detail:

1. The Factorial Principle

At the heart of DOE lies the factorial principle. This principle is about exploring the effects of multiple factors simultaneously rather than one at a time. It’s a powerful approach that reveals the impact of individual factors and how they interact with one another.

For instance, temperature and pressure might be two such factors in a chemical process. The factorial principle allows us to understand if there’s a synergy between these variables, leading to more comprehensive insights than if we were to examine them in isolation.

2. Randomization

Image Source: PxHere

Randomization is a fundamental aspect of DOE that contributes to its scientific rigor. By randomizing the order in which experiments are conducted, we can mitigate the influence of uncontrolled or unknown variables. This is crucial for maintaining the experiment’s integrity and ensuring the results are statistically valid.

In practice, this might mean randomizing the sequence of trials in a clinical study to prevent biases from affecting the outcomes.

3. Replication

Replication involves repeating experiments to confirm the reliability and consistency of the results. This principle is essential for increasing the precision of estimates and establishing confidence in the findings.

Replication can help distinguish between real effects and random variation, a distinction critical in fields like pharmaceuticals and materials science, where decisions based on experimental results can have significant implications.

4. Blocking

Blocking is a technique used to control the influence of nuisance variables. By grouping experimental units similar in terms of these nuisance variables, we can effectively isolate the effect of the factors being studied.

For example, in agricultural experiments, plots of land with similar soil quality might be grouped (blocked) to control for variations in soil conditions.

Each of these principles contributes to the robustness and validity of the experimental design, making DOE a powerful tool for researchers and practitioners across various disciplines.

The Steps of DOE

Having explored the foundational principles of DOE, we now turn our attention to the practical application of these principles through the steps of the DOE process. The implementation of DOE is a structured journey, each step building upon the last to ensure a comprehensive understanding of the experimental outcomes.

Setting Clear Objectives

The first step in DOE is to set clear, specific objectives. What are the questions we aim to answer? What are the outcomes we seek to achieve? This stage involves defining the scope of the experiment, the variables of interest, and the desired results. For instance, manufacturers should increase production efficiency while maintaining product quality.

Selecting Process Variables

Once the objectives are set, the next step is to select the process variables or factors that will be tested. These are the inputs or conditions that may influence the outcomes. In a baking process, for example, these could include oven temperature, baking time, and ingredient proportions.

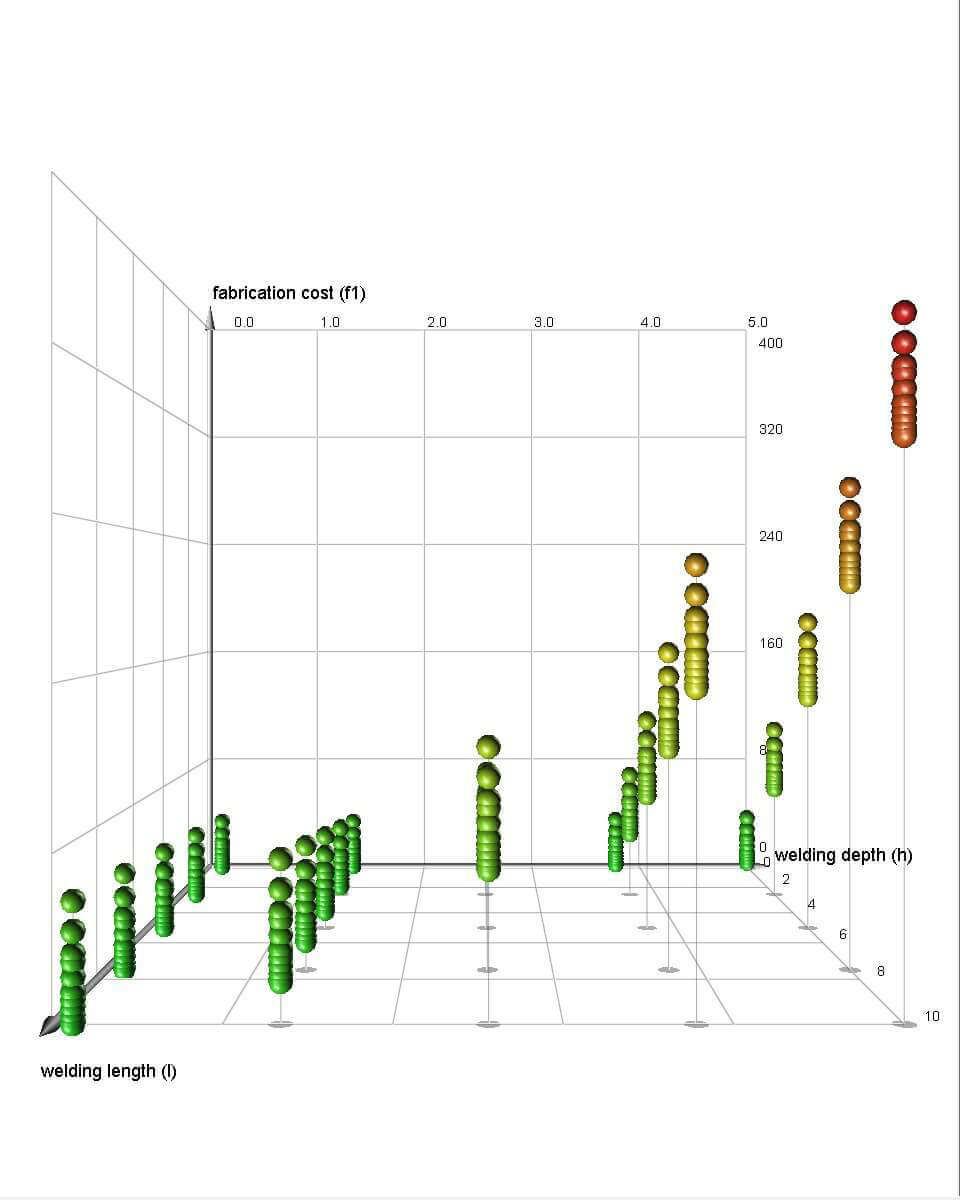

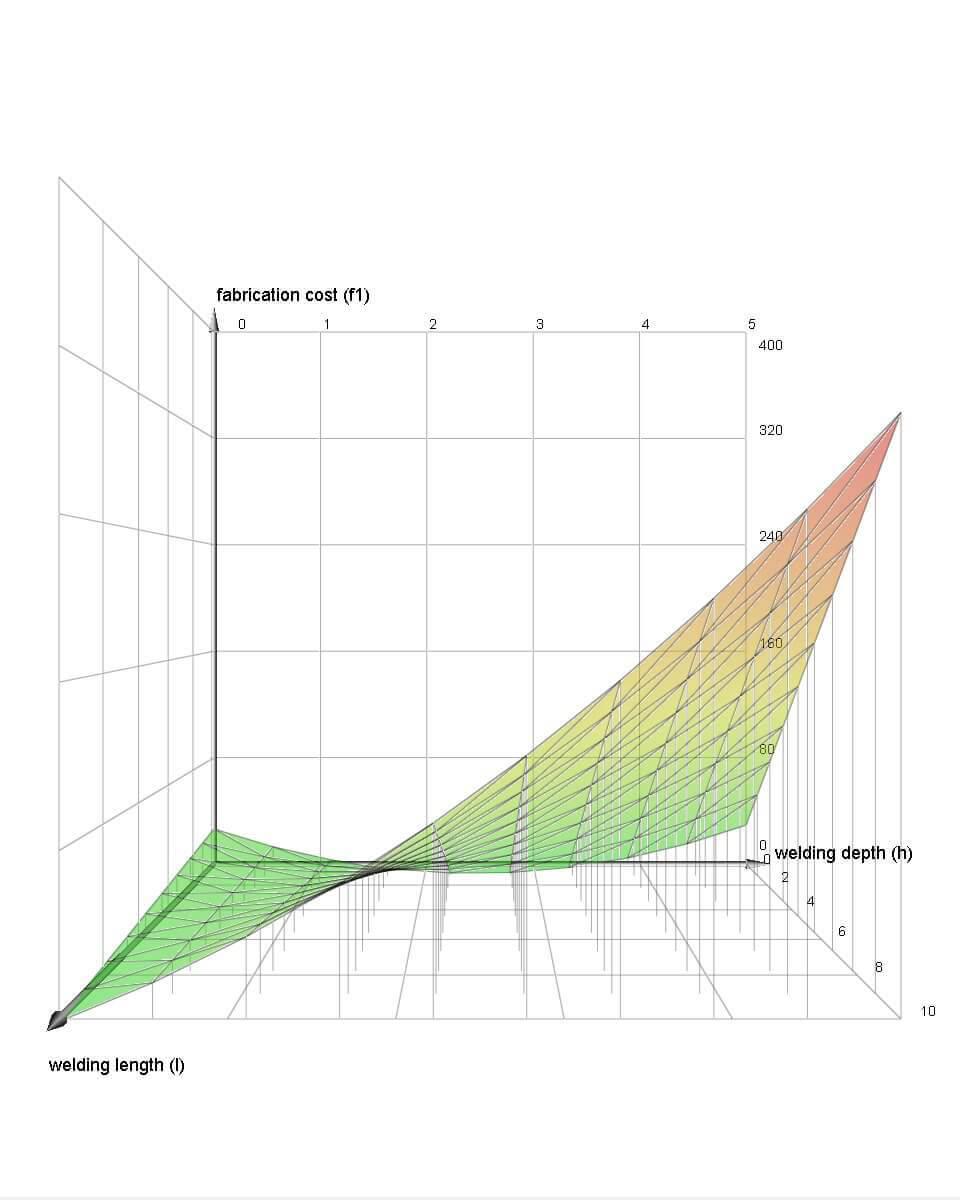

Choosing the Experimental Design

With the objectives and variables in place, the next step is selecting an appropriate experimental design. This design will dictate how the variables are manipulated and measured. Common designs include full factorial, fractional factorial, and response surface methodology. Each design has advantages and is chosen based on the experiment’s complexity and resource availability.

Executing the Design

This step involves the practical aspect of running the experiment according to the chosen design. It’s crucial to adhere closely to the plan to ensure the data collected are valid and reliable.

Checking Data Consistency

After executing the experiment, it’s important to check that the collected data are consistent with the experimental assumptions. This involves validating the data quality and ensuring that the experimental conditions were controlled as planned.

Analyzing and Interpreting Results

The penultimate step is to analyze the data using statistical methods. This analysis helps understand the relationships between variables and draw meaningful conclusions. It’s where the power of DOE truly shines, as it can reveal insights that may not be apparent from a simple examination of the raw data.

Using and Presenting Results

The final step is to use and present the results meaningfully. This could involve changing a manufacturing process, developing new products, or gaining new scientific insights. The results should also be communicated effectively to stakeholders, including writing reports, presenting findings, or implementing changes based on the results.

By following these steps methodically, DOE can significantly improve processes and products, offering a systematic approach to experimentation and discovery. In the next sections, we will delve deeper into each step, exploring their intricacies and providing practical tips for successful implementation.

Practical Considerations in DOE

Practical considerations are essential for successfully applying DOE principles in real-world settings. Paying attention to these details can significantly improve the quality and relevance of your experimental outcomes.

- Performance of Measurement Devices: Ensure that all equipment and measurement devices are calibrated and functioning properly to obtain accurate data.

- Simplicity is Key: Design experiments as simply as possible without compromising the objectives. Complexity can often lead to confusion and errors.

- Feasibility of Runs: Before executing the design, confirm that all planned runs are practical and the necessary resources are available.

- Monitoring for Drifts and Shifts: During the experiment, monitor process drifts or shifts. These can introduce unwanted variability into the results.

- Avoiding Unplanned Changes: Changes in personnel, materials, or methods during the experiment can introduce biases. Try to keep all conditions constant.

- Planning for Contingencies: Allow time and resources for unexpected events. This could include additional runs or troubleshooting equipment issues.

- Stakeholder Engagement: Obtain buy-in from all parties involved, including team members, management, and other stakeholders. This ensures support and resources for the experiment.

- Data Integrity: Preserve all raw data and maintain detailed records of each step in the experiment. This is crucial for analysis, replication, and validation of results.

- Post-Experiment Procedures: After completing the experiment, reset equipment and conditions to their original state, restoring the operational environment.

Considering these practical aspects, DOE can be effectively integrated into various operational settings, leading to meaningful and actionable results.

Advancing Your DOE Practice: From Theory to Implementation

Image source: Medium

Having explored the principles, steps, and practical considerations of the Design of Experiments (DOE), this final section focuses on advancing theoretical understanding to effective implementation. Here, we discuss integrating DOE into your regular practice, ensuring its benefits are fully realized in real-world applications.

- Integrating DOE into Existing Processes: Identify areas where DOE can be implemented within your existing processes. This could be in product development, quality improvement, or process optimization. The goal is to find opportunities where DOE can add value.

- Training and Skill Development: Ensure that the team members involved in the experiments are adequately trained in DOE principles and techniques. This might involve formal training sessions, workshops, or self-learning modules.

- Collaboration with Cross-Functional Teams: DOE often requires collaboration across different departments or disciplines. Encourage communication and teamwork to leverage diverse expertise, which is crucial for complex experiments.

- Utilizing Software and Tools: Modern DOE is greatly enhanced by statistical software that can help design, analyze, and interpret experiments. Familiarize yourself with these tools to improve efficiency and accuracy.

- Continuous Learning and Adaptation: Stay updated with the latest developments in DOE methodologies. Attend seminars, read relevant literature, and participate in professional forums. Continuous learning helps in refining your approach and keeping your methods up-to-date.

- Documenting and Sharing Results: Document the outcomes of your DOE practices, including successes and challenges. Sharing these results within your organization can foster a culture of learning and continuous improvement.

- Evaluating and Refining DOE Practices: Regularly evaluate the effectiveness of your DOE practices. Seek feedback, and be open to refining your approach based on what you learn from each experiment.

- Scaling DOE Practices: As you gain confidence and experience, consider scaling up your DOE practices to more complex or broader areas within your organization. This could mean larger experiments, more variables, or cross-functional projects.

- Fostering a Culture of Experimentation: Encourage a culture where experimentation and data-driven decision-making are valued. This cultural shift can lead to more innovative approaches and better overall outcomes.

- Ethical Considerations and Compliance: Always conduct your experiments ethically and in compliance with relevant regulations and standards. This includes considerations for safety, data privacy, and ethical use of resources.

Conclusion

The power of DOE lies in its structured approach and ability to turn complex variables into actionable insights. By embracing the principles, steps, and practical considerations of DOE, practitioners can significantly enhance the quality and efficiency of their experimental work.

Remember, the iterative nature of DOE is not just a methodology but a mindset that encourages continuous learning and adaptation. Integrating DOE into your practices opens doors to innovation and more profound understanding in your field. Let this guide be a stepping stone to more informed, precise, and effective experimentation, driving forward the frontiers of your work.

Consider enrolling in Air Academy Associates’ Operational Design of Experiments Course to deepen your understanding and practical application of DOE. This course offers an immersive learning experience, guiding you from fundamental concepts to advanced applications in DOE. Enhance your skills and bring a new level of expertise to your work. Learn more and sign up today at Air Academy Associates.