Response Surface Methodology (RSM) is a collection of statistical and mathematical techniques for developing, improving, and optimizing processes. It primarily focuses on modeling and analyzing the effects of several independent variables on response variables. Originating from the work of Box and Wilson in 1951, RSM has evolved into a pivotal tool in operational research, enabling the systematic experimentation and investigation of process conditions to determine optimal operational settings.

RSM’s importance in operational research lies in its ability to identify the relationship between process variables and outcomes, facilitating the prediction of performance and quality metrics under various conditions. By employing techniques such as polynomial regression, RSM helps construct an approximate response surface model. Through optimization techniques, it then seeks to find the optimal process settings that enhance operational efficiency and product quality, making it invaluable for process improvement initiatives.

Takeaways

- Effective RSM requires understanding its complexities and applying strategic solutions to enhance operational processes.

- Advanced statistical techniques and robust experimental designs are vital to overcoming challenges and avoiding common pitfalls in RSM.

- Regular model validation and expert knowledge incorporation significantly improve RSM outcomes’ accuracy and reliability.

- Staying updated with the latest advancements in RSM methodology ensures continuous improvement in process optimization efforts.

Foundational Concepts of RSM

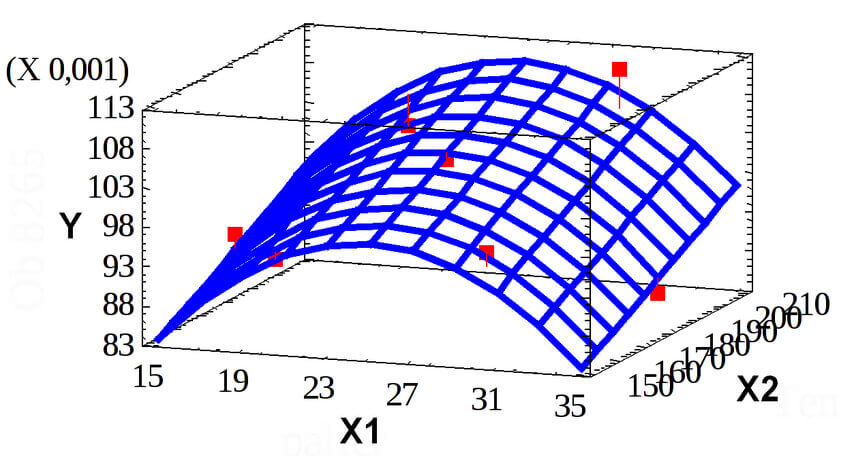

Image Source: Wikimedia Commons

The foundational concepts of Response Surface Methodology (RSM) encompass several key areas:

- Design of Experiments (DoE): This is a statistical strategy that combines experimental designs with regression analysis to explore relationships between one or more variables and responses. It aims to optimize process performance or response through a structured experimentation framework.

- Polynomial Regression and Model Building: Polynomial regression is a form of regression analysis where the relationship between the independent variable x and the dependent variable y is modeled as an nth-degree polynomial. RSM uses this to create models that predict outcomes within the experimental space.

- Optimization and Surrogate Modeling: RSM seeks to find optimal conditions that yield the best response for a given process. Surrogate modeling involves creating a simple model (surrogate) that approximates the actual physical process or system being studied, which is particularly useful when direct measurements of the system are difficult or expensive to obtain.

These areas work together to allow researchers and practitioners to systematically study and optimize processes by understanding the effects of multiple variables on outcomes. This facilitates informed decision-making and improvements in operational efficiency.

Applications of RSM in Operational Experimentation

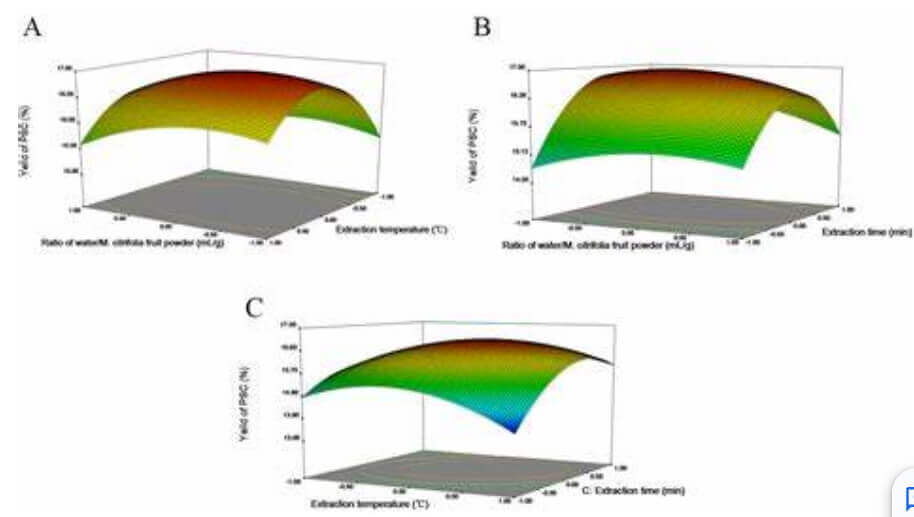

Image Source: perrj.com

Response Surface Methodology (RSM) finds extensive applications across various industries, leveraging its capacity for modeling and optimizing processes involving multiple input variables. Here are examples of how RSM is applied in operational experimentation across different sectors:

- Civil Engineering: RSM has been utilized for reliability analysis in civil engineering projects, such as studying soil slopes and laterally loaded piles. It aids in evaluating the allowable bearing pressures on shallow foundations, providing a framework for comparing conventional solutions with numerical analysis results to make rational decisions on permissible loads.

- Environmental Engineering: In environmental applications, RSM optimizes conditions for the degradation of pollutants. For instance, the methodology has been applied to maximize the photodegradation efficiency of dyes in water, adjusting parameters like the concentration of catalysts and irradiation time to achieve optimal degradation rates.

- Food Industry: The food industry benefits from RSM in product formulation and process optimization. It’s instrumental in identifying key variables affecting food quality and optimizing processing conditions for attributes such as taste, texture, and nutritional value.

RSM aids in developing new food products by efficiently screening and modeling the effects of various ingredients and processing parameters on desired outcomes.

- Manufacturing: In the manufacturing sector, RSM guides the optimization of machining and production processes, such as CNC turning operations. By selecting appropriate process parameters (e.g., cutting speed, feed rate, depth of cut), RSM helps achieve optimal product qualities like surface finish, enhancing manufacturing efficiency and product performance.

- Pharmaceuticals and Chemical Industries: RSM is widely used for optimizing drug formulation and chemical processes. By modeling the relationship between formulation variables and product attributes, companies can optimize the composition of drugs for maximum efficacy and stability.

Similarly, in chemical manufacturing, RSM facilitates the optimization of reaction conditions to maximize yield and purity while minimizing waste and energy consumption.

These examples illustrate RSM’s versatility and pivotal role in enhancing operational efficiency, product quality, and environmental sustainability across various industries. By systematically exploring the effects of multiple variables on a response, RSM enables organizations to make informed decisions, streamline their operations, and innovate in product development.

Step-by-Step Guide to Implementing RSM

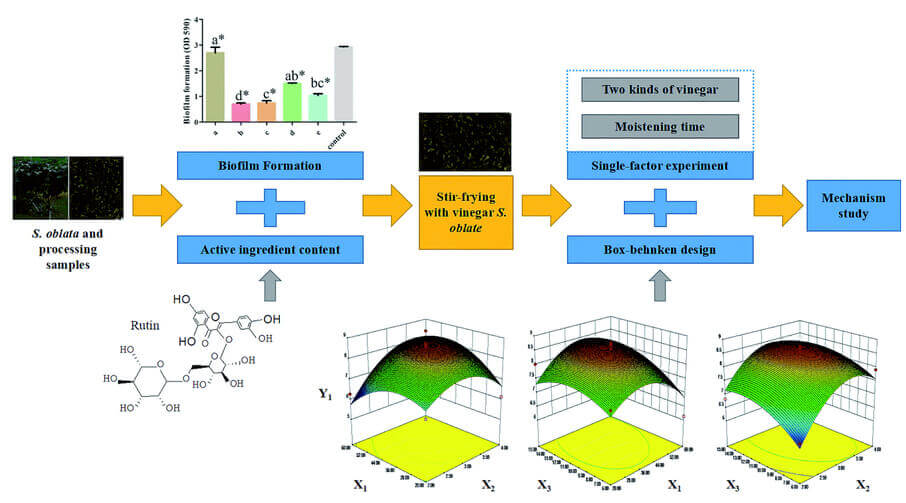

Image Source: Royal Society of Chemistry

Implementing Response Surface Methodology (RSM) involves a strategic approach to optimize processes through a series of steps, integrating both first-order and second-order models based on the complexity of the response surface.

Here’s a step-by-step guide synthesized from various sources, including insights from the Design of Experiments and online lessons on statistical methods.

Identify the Starting Point

Begin with your current experimental conditions as the initial point. These conditions must be reproducible; otherwise, the results of RSM will not be reliable.

Choose a Model for Approximation

Decide between a first-order model for initial exploration or a second-order model for more precise optimization near the peak of the response surface. The choice depends on the proximity to the optimal conditions and the complexity of the response surface.

Design of Experiments (DoE)

Based on the chosen model, design your experiments to allow for the estimation of the model’s parameters.

For a first-order model, this involves simpler designs with fewer runs, suitable for exploring far from the optimum. For a second-order model, more complex designs, such as Central Composite Designs (CCD), require more runs but provide a detailed view of the response surface near the optimum.

Execute Experiments and Collect Data

Carry out the experiments as per your design. This step is crucial for gathering the necessary data to model the response surface accurately.

Analyze Data and Model the Response Surface

Use the collected data to estimate the parameters of your chosen model. This involves statistical analysis, typically through regression techniques, to understand how the independent variables influence the response.

Determine the Path of Steepest Ascent/Descent

For a first-order model, identify the direction in which the response rapidly increases (or decreases). Calculate the gradient of the response surface. In subsequent iterations, you can refine this direction based on updated models.

Iterate with More Precise Models

Once you’re closer to the optimum, switch to a second-order model to better capture the curvature of the response surface. This will allow for a more accurate determination of the optimum conditions.

Optimization and Confirmation

After identifying the optimum conditions through the second-order model, conduct additional experiments to confirm these conditions. This step ensures the reliability of your optimization effort.

Implement and Monitor

Once the optimal conditions are confirmed, implement them in your operational process. Continuous monitoring is essential to ensure the process remains optimum over time.

Advanced Topics in Response Surface Methodology

Bayesian Optimization

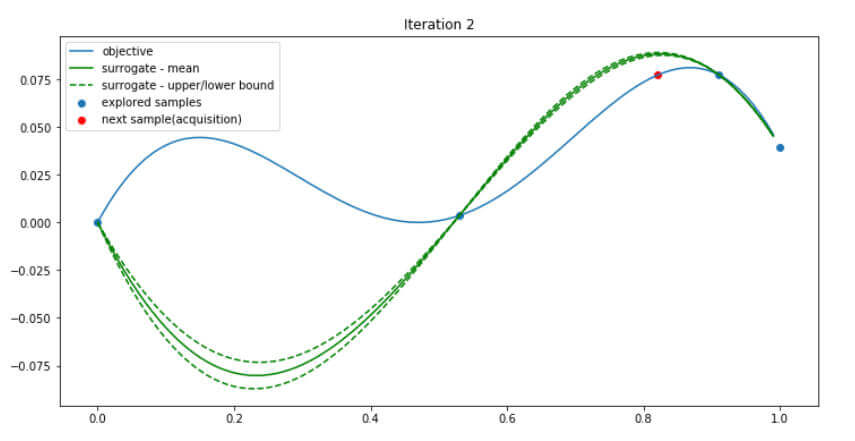

Bayesian Optimization in RSM is a global optimization strategy that does not assume any functional forms of the objective function, making it suitable for optimizing expensive-to-evaluate functions. It is particularly beneficial in scenarios where the functional form of the objective is unknown or costly to evaluate, such as in chemical synthesis or machine learning model tuning.

Image Source: Eric Websmith Studio

Using a sequential design strategy, Bayesian Optimization efficiently navigates the search space, significantly reducing the number of experiments or simulations needed to locate the optimum conditions.

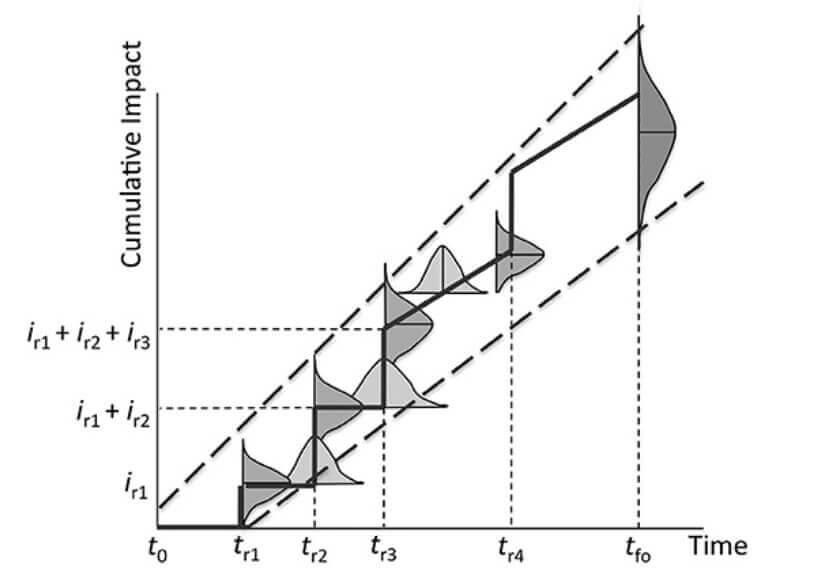

Probabilistic Design

Probabilistic Design in RSM focuses on incorporating uncertainty in optimization processes. Understanding the variability in experimental outcomes enhances uncertainty-based decision-making, leading to more robust and reliable designs. This approach is critical in fields where outcomes are unpredictable, ensuring that designs are optimized for best-case scenarios and resilient against variations in inputs or conditions.

Image Source: Frontiers

Probabilistic design significantly improves the efficiency and effectiveness of experimental and operational strategies, particularly in complex systems where the exact responses are not straightforwardly predictable.

Challenges and Solutions in RSM

Response Surface Methodology (RSM) is a powerful tool in operational research for modeling and optimizing complex systems. However, when using it, there are inherent challenges, pitfalls, and limitations. Here’s a breakdown:

Challenges

- Selecting the suitable model: Choosing an appropriate response surface model is crucial, but limited data or complex interactions can complicate it.

- Experimental design: Setting up efficient and informative experiments to estimate model parameters requires careful planning and considering cost and time constraints.

- Interpreting results: Understanding the statistical significance of results and avoiding overfitting the model is crucial in drawing valid conclusions.

- Non-linearity and interactions: RSM assumes relatively smooth and continuous responses, but real-world systems often have non-linearity and complex interactions, requiring additional techniques or alternative methods.

- High dimensionality: Dealing with multiple factors and interactions adds complexity and can increase the number of required experiments.

Solutions

- Exploratory data analysis: Thoroughly analyze the data before model selection to understand its characteristics and potential issues.

- Design of experiments (DOE) software: Utilize specialized software to optimize experimental designs based on desired accuracy and constraints.

- Model diagnostics and validation: Perform tests to assess model adequacy, check for assumption violations, and validate the model with separate data.

- Advanced modeling techniques: For non-linearity or high dimensionality, consider methods like splines, kriging, or machine learning approaches.

- Data transformation: Transform variables when necessary to meet model assumptions and improve analysis.

Common Pitfalls

- Ignoring potential outliers: Failing to identify and address outliers can significantly impact model accuracy.

- Using an inappropriate model: Blindly applying a standard model without considering the specific problem can lead to misleading results.

- Overfitting the model: Focusing too much on fitting the model to the data can result in poor generalizability.

- Misinterpreting interactions: Not carefully interpreting interaction terms can lead to incorrect conclusions about the relationships between factors.

- Inadequate experimental design: Inefficiently designed experiments waste resources and provide unreliable data.

Addressing Limitations and Enhancing Accuracy

- Combine RSM with other techniques: Use complementary methods like simulation or optimization to address RSM’s limitations, like handling discrete variables or complex constraints.

- Increase data quality: Collect high-quality, accurate data to improve model reliability.

- Replicate experiments: Conduct repeated experiments to verify results and assess model robustness.

- Incorporate expert knowledge: Leverage domain expertise to guide modeling decisions and interpret results.

- Stay updated with advancements: Utilize new developments in RSM and experimental design to improve your approaches.

By understanding these challenges, solutions, pitfalls, and enhancements, you can effectively leverage RSM for accurate and reliable optimization in your operational research endeavors. Practical application requires careful planning, awareness of limitations, and considering alternative methods when necessary.

Conclusion

Effectively leveraging Response Surface Methodology (RSM) involves navigating its complexities strategically and addressing challenges through advanced statistical and experimental techniques.

By avoiding common pitfalls such as overfitting and inappropriate model selection through vigilant exploratory data analysis and validation, the accuracy and reliability of RSM can be significantly enhanced. Incorporating expert knowledge and staying abreast of the latest methodological advancements will further empower researchers and practitioners to harness the full potential of RSM in optimizing operational processes and outcomes.

Maximizing the efficacy of operational processes through Response Surface Methodology (RSM) requires a nuanced understanding of its challenges and a strategic application of its solutions. By integrating advanced statistical techniques and ensuring robust experimental design, practitioners can overcome common pitfalls, enhancing the accuracy and reliability of their outcomes.

Discover how to elevate your operational experiments with Air Academy Associates’ comprehensive course on Operational Design of Experiments. Embrace the opportunity to refine your skills and drive efficiency in your processes.