For experienced professionals pursuing Six Sigma Black Belt certification, gaining expertise in advanced process control techniques is imperative. Black Belts are technical leaders managing complex improvement projects across key business processes and systems.

Robust process control capabilities enable Black Belts to enhance consistency, minimize variability, reduce defects, and drive major efficiencies. This analytical and statistical control expertise empowers Black Belts to spearhead transformative performance gains.

This post will explore the sophisticated process control tools that students master through a Black Belt curriculum. We’ll cover analytical assessment methods, statistical techniques, implementation approaches, and sustaining controls over the long term.

Gaining insight into these game-changing tools will illustrate the immense value Black Belts bring through their specialized process control competencies. Let’s get started.

Understanding the Fundamentals of Process Control

Image Source: Freepik

Process control is at the core of Six Sigma methodology. It serves as the compass guiding organizations toward operational excellence and efficiency. This section will revisit key process control concepts to provide a solid foundation for our journey into advanced process controls.

Why Process Control Matters

Process control revolves around the central idea of managing and reducing variations within a system. These variations can arise from various sources, both internal and external, and can lead to defects, inefficiencies, and unpredictability.

Organizations aim to operate within predefined parameters by diligently monitoring and adjusting processes. This reduces variability and minimizes defects, ensuring that the end product or service meets or exceeds customer expectations.

The Role of Black Belts

Black Belts, the adept Six Sigma practitioners, play a pivotal role in implementing and maintaining effective process control. They are equipped with a diverse toolkit encompassing analytical techniques and statistical methods. This holistic approach allows Black Belts to assess and control processes comprehensively.

- Analytical Techniques: Black Belts uses tools like Failure Mode and Effects Analysis (FMEA) to identify potential risks and failure modes within a process. This foresight enables them to take preventive measures before issues arise.

- Statistical Methods: Statistical tools, including control charts, are the backbone of process control. They provide real-time insights into process performance. By continuously monitoring these charts, Black Belts can swiftly detect deviations and take corrective actions, ensuring processes remain within acceptable limits.

The Benefits of Effective Process Control

Image Source: Deanlong.io

Why invest in process control? The answer is simple: Process controls bring a wealth of benefits to an organization.

- Consistency: Consistent processes lead to consistent outcomes. Whether manufacturing a product or providing a service, customers appreciate reliability. Process control ensures that your outputs meet predetermined quality standards repeatedly.

- Reliability: Reliable processes instill confidence in your customers and stakeholders. They know that when they engage with your organization, they can expect a dependable experience.

- Efficiency: Process control helps organizations operate more efficiently by minimizing variations and reducing defects. This translates to cost savings and improved resource utilization.

- Quality: High-quality outputs are a hallmark of successful organizations. Process controls are your guardians against subpar quality, ensuring that your products or services consistently meet or exceed customer expectations.

- Stability Amidst Change: In a dynamic business environment, change is constant. Effective process controls provide stability, even in the face of evolving conditions. They act as the rudder guiding your ship through turbulent waters.

Analytical Process Control Tools

Analytical tools proactively assess process failure risks before implementing new improvements, products, or systems. Black Belts become adept at several techniques:

Failure Modes and Effects Analysis (FMEA)

FMEA provides a structured methodology to evaluate potential failure modes based on severity, likelihood of occurrence, and detection capability. By brainstorming vulnerabilities, teams can prioritize and mitigate the highest-risk failures through preventative measures.

Black Belts guide cross-functional teams through mapping out all process steps and inputs. Next, they identify possible failure modes at each step and score the risk priority number (RPN) as severity x occurrence x detection.

The output is a detailed FMEA analysis highlighting the most critical failure modes to address and specific actions. Common preventative measures include:

- Adding process controls and safeguards.

- Improving detection systems.

- Designing risk out of processes.

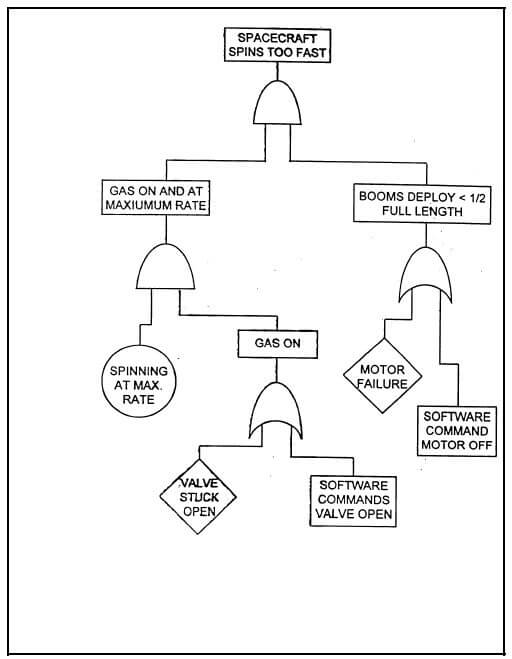

Fault Tree Analysis

This technique involves deductive reasoning to map linkages between process failures, equipment malfunctions, and human errors leading to a defect.

Image Source: Wikimedia Commons

Black Belts construct visual fault tree diagrams starting with the defect. Branches show causal relationships between major subsystems and root causes. This helps pinpoint what failed and how the different variables interacted.

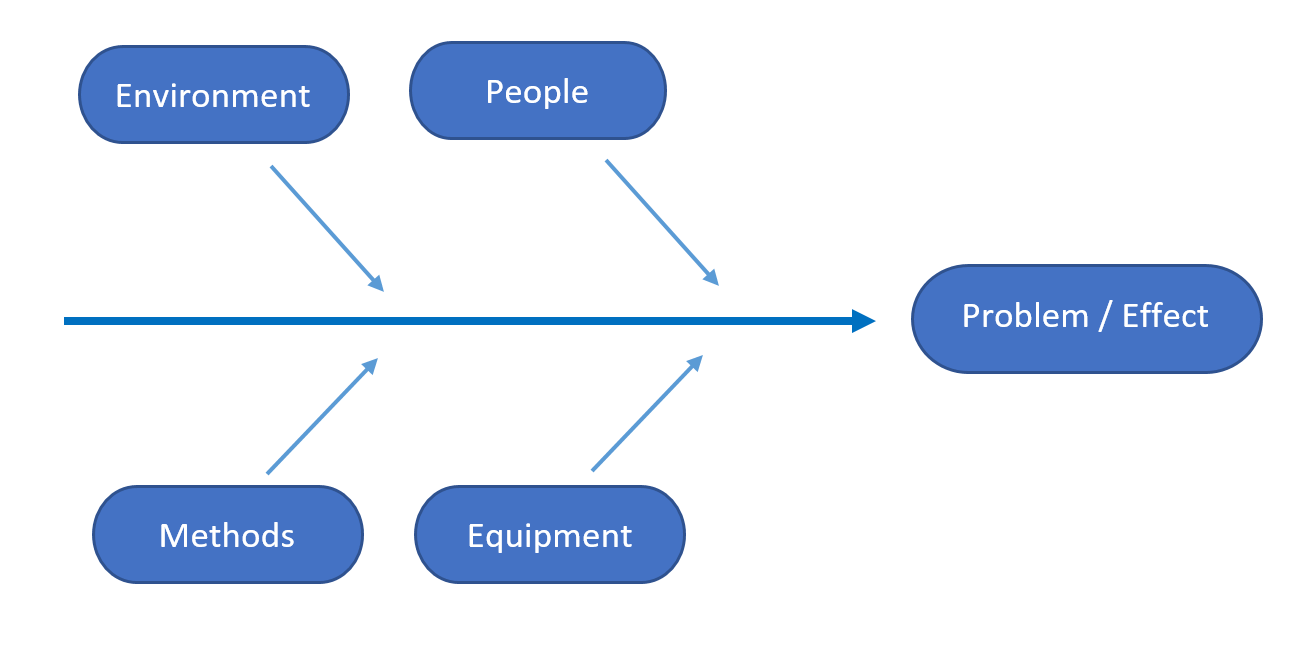

Ishikawa Fishbone Diagrams

Also known as cause-and-effect diagrams, fishbone diagrams illustrate how various inputs may contribute to an output effect. Black Belts learn to lead sessions to brainstorm potential causes, grouped into major categories like Materials, Machines, People, Methods, Measurement, and Environment.

Image Source: Wikimedia Commons

By visually linking causes and effects, Black Belts gain sharper insight into root causes to derive targeted solutions.

Statistical Process Control Techniques

In addition to pre-implementation analytical tools, Black Belts become technically proficient in several statistical methods to monitor live process performance:

Control Charts

Control charts plot process data over time, with statistically derived upper and lower control limits (UCL and LCL). This visual makes patterns, anomalies, and trends apparent. A process operating within the control limits is stable, while points outside signify special cause variation needing investigation.

There are two main types:

– Variable charts monitor measurable characteristics like dimensions or temperatures. XmR charts are commonly used.

– Attribute charts monitor pass/fail or defect rates. P-charts and c-charts are typically leveraged.

Control charts help Black Belts discern common cause vs. special cause variation and take action before processes go out of control.

Capability Analysis

By mathematically analyzing the relationship between process performance and specification limits, Black Belts quantifies the ability to meet requirements consistently. Common metrics include:

– Cp – Potential capability ratio

– Cpk – Actual capability accounting for mean centering

– Pp and Ppk – Capability indices based on achieved performance

Capability analysis flags processes requiring improvement before new product launches or those experiencing creeping variation.

Lean Tools

Black Belts synthesize Lean concepts like takt time, pull systems, visibility, and poka-yoke mistake-proofing to reduce process waste and variation.

Design of Experiments (DOE)

DOE employs controlled testing to model relationships between inputs and outputs. Designed experiments reveal vital factors with dominant effects to optimize configurations.

Regression analysis shows input-output correlations. Black Belts become adept at two-level factorial and fractional factorial experimental designs.

Equipped with both proactive analytical tools and real-time statistical techniques, Black Belts can implement integrated control solutions.

Implementing Advanced Process Control Systems

With their robust process control knowledge, Black Belts can deploy comprehensive control systems:

– Use FMEA and fault tree analysis during design stages to prevent failures by adding controls based on projected risks

– Build real-time statistical process monitoring and alerts using control charts and capability metrics

– Continuously optimize vital input factors for maximum performance via DOE

– Incorporate Lean principles like visual displays, standard work, and mistake-proofing to sustain reliability

Black Belts ensures integration with existing infrastructure like automation, ERP, logistics flows, and quality management platforms. This harmonization amplifies technical capabilities through connected controls.

Sustaining Long-Term Process Controls

Image Source: Freepik

Process controls, once established, require ongoing attention and maintenance to prevent decay. The responsibility for maintaining these controls falls squarely on the shoulders of Six Sigma Black Belts. They play a critical role in ensuring that the organization’s processes continue to operate smoothly and efficiently over the long term.

Here are some key elements that Black Belts implement to sustain controls effectively:

1. Embedding Procedures into Standard Work

Black Belts integrate control procedures seamlessly into standard work instructions, employee training programs, and official documentation. This ensures that everyone involved is aware of and follows the established controls.

2. Leveraging Digital Tools

Black Belts implements digital dashboards, analytics tools, and automated alerts to enhance visibility and real-time monitoring. These tools provide instant insights into process performance, allowing rapid response to deviations.

3. Roles and Responsibilities

Clearly defined roles and responsibilities are essential for control maintenance. Black Belts assign individuals or teams to monitor controls, conduct regular audits, generate reports, and drive system improvements. This accountability ensures that controls are not overlooked.

4. Continuous Analysis and Review

Regular capability analysis, control charting, and Failure Mode and Effects Analysis (FMEA) reviews are integral to control sustenance. These activities help identify trends, potential risks, and areas for improvement.

5. Rapid Anomaly Response

Inevitably, anomalies and deviations will occur. Black Belts establish mechanisms to respond to detected anomalies quickly. This might involve predefined action plans and escalation procedures to rectify issues promptly.

6. Data Collection and User Feedback

Data is the lifeblood of process control. Black Belts ensure that data collection is ongoing and accurate. Additionally, they actively seek and incorporate user feedback to make necessary enhancements to controls.

By diligently implementing these elements, Black Belts institutionalize controls, metrics, and a continuous improvement mindset within the organization. This ensures the longevity of process controls and contributes to a culture of sustained excellence.

In essence, sustaining controls is not a one-time effort but an ongoing commitment to excellence. It’s a testament to the organization’s dedication to consistently delivering quality products or services.

The Immense Value of Process Control Expertise

Six Sigma Black Belts gain an extraordinarily valuable skillset by mastering proactive analytical and real-time statistical process control techniques.

They can stabilize processes for predictable outputs, drastically reduce chronic defects, enable data-driven improvement, and achieve substantial efficiency gains. This capability accelerates ROI across operational domains, from manufacturing to healthcare to financial services.

For experienced quality professionals looking to maximize business impact, pursuing Black Belt training featuring hands-on mastery of advanced process control tools represents a strategic opportunity.

Hopefully, this deep dive provided meaningful insights into the sophisticated technical expertise Black Belts gain through an intensive Six Sigma curriculum. Process control capabilities empower Black Belts to lead breakthrough transformations.

Take your process control skills to the next level with Advanced Process Control Tools, featured in our Black Belt Curriculum blog. Discover innovative strategies and techniques that will revolutionize your problem-solving approach. Don’t miss the chance to become a certified Lean Six Sigma Black Belt. Enroll in our online course today and accelerate your professional growth!