Design of Experiments (DOE) is essential for understanding how multiple variables affect outcomes in scientific and industrial processes. By integrating multivariate analysis, the depth of data interpretation is significantly enhanced, allowing for a detailed understanding of complex interactions. This approach is crucial for uncovering hidden insights within data, leading to better decision-making and improved results.

This blog focuses on the critical role of multivariate analysis in DOE, aiming to equip readers with the knowledge to apply these advanced statistical methods in their process improvement projects. Through a concise overview of its applications and benefits, we aim to enable more precise and efficient optimization of processes using multivariate techniques.

Foundations of Multivariate Analysis

Image Source: Flickr

Multivariate analysis encompasses a range of statistical techniques designed to analyze data that involves multiple variables. This method is crucial for understanding the complex interactions between variables in various fields such as marketing, healthcare, finance, and social sciences.

What is Multivariate Analysis?

Multivariate analysis allows for examining more than two variables simultaneously to understand their interrelationships. Unlike univariate (one variable) and bivariate (two variables) analyses, multivariate analysis can uncover patterns, correlations, and interactions among several variables, providing a deeper and more comprehensive understanding of the data.

Fundamental Techniques in Multivariate Analysis

Several key techniques form the core of multivariate analysis, each suited for different types of data and research questions:

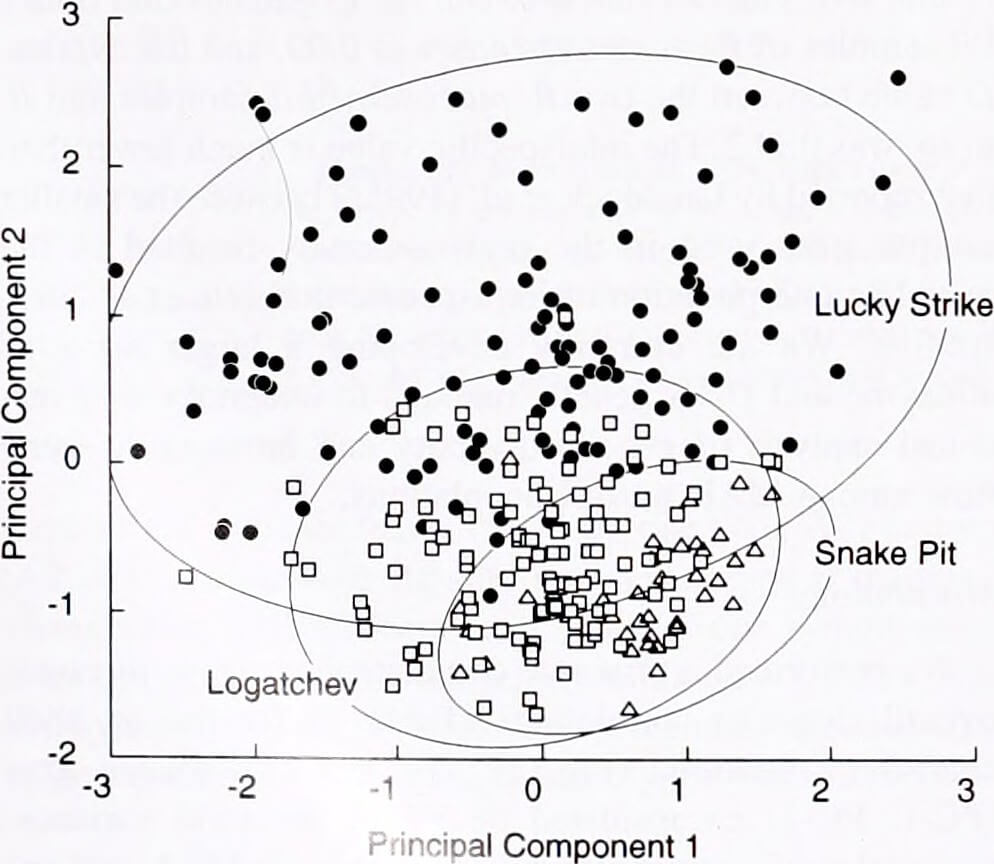

- Principal Component Analysis (PCA) and Factor Analysis (FA) are used for dimensionality reduction. These techniques identify underlying patterns or structures in the data, simplifying complex datasets by reducing the number of variables to a smaller set of factors or principal components without losing much information.

- Cluster Analysis groups similar cases or variables together based on their characteristics. This method is beneficial for identifying natural groupings within the data, such as customer segmentation in marketing.

- Discriminant Analysis and Canonical Correlation Analysis are used for classification and understanding the relationships between two sets of variables, respectively. These techniques can help identify the variables that best distinguish between predefined groups or explore the interrelations between variable sets.

- Multivariate Analysis of Variance (MANOVA) extends the ANOVA technique to multiple dependent variables, testing the effect of independent variables on more than one outcome variable. This is particularly useful in experiments where the effects on several outcomes must be considered simultaneously.

Exploratory Data Analysis (EDA)

Before applying more complex multivariate techniques, Exploratory Data Analysis (EDA) is conducted to summarize the dataset’s main characteristics. EDA involves visualizing data, identifying patterns, and checking for anomalies or outliers. It lays the groundwork for further analysis by providing insights into the data’s distribution, variability, and potential relationships.

Interpreting Multivariate Analysis Results

Interpreting the results of multivariate analysis involves understanding the relationships, patterns, and trends among the variables. This process requires careful consideration of the statistical significance of the findings, the context of the analysis, and the application of domain knowledge. Effective communication of the results, highlighting key insights and actionable recommendations, is crucial for stakeholders to make informed decisions.

Advantages and Limitations

Multivariate analysis offers the advantage of a comprehensive analysis of complex datasets, identifying patterns not discernible in univariate or bivariate analyses. However, it requires large sample sizes and is sensitive to the quality of the data. The complexity of the techniques also poses interpretation challenges, especially for those without advanced statistical training.

Applications of Multivariate Analysis

Multivariate analysis has many applications, ranging from market research and customer segmentation to healthcare research, financial risk management, and social sciences studies. It allows for investigating complex phenomena and developing predictive models, providing valuable insights to inform decision-making and strategy.

Integrating Multivariate Analysis with DOE

Image Source: Freepik

Integrating multivariate analysis into the Design of Experiments (DOE) enhances the analysis of experimental data by allowing the simultaneous examination of multiple response variables. This approach provides a more nuanced understanding of the system or process under study beyond the limitations of analyzing single response variables. Here, we focus on strategies for incorporating multivariate analysis into DOE and discuss case studies that illustrate the integration of multivariate techniques.

Strategies for Incorporating Multivariate Analysis into DOE

- Pre-Experiment Planning: Effective integration starts with careful planning. Identify the primary objectives of the experiment and consider how multivariate analysis can help achieve these goals. Determine the variables to be measured and how they can be analyzed to provide insights into complex interactions.

- Selection of Appropriate Multivariate Techniques: Choose multivariate analysis techniques best suited to the experiment’s objectives and the data’s nature. For example, Principal Component Analysis (PCA) can be used for dimensionality reduction in experiments with many variables. At the same time, Multivariate Analysis of Variance (MANOVA) can test the effect of experimental factors on multiple response variables.

- Data Collection and Preparation: Ensure data collection methods are compatible with multivariate analysis requirements. This includes planning for adequate sample sizes and ensuring data quality. Data preparation steps such as normalization or transformation may be necessary to meet the assumptions of the chosen multivariate techniques.

- Analysis and Interpretation: Perform the multivariate analysis using statistical software capable of handling complex datasets. Interpret the results in the experiment context, paying close attention to the interactions between variables and their impact on the response variables.

- Iterative Refinement: Use the insights gained from the multivariate analysis to refine the experimental design. This iterative process can lead to more focused experiments, targeting specific factors or interactions of interest.

Case Studies Illustrating the Integration

In a manufacturing process optimization study, multivariate analysis was used to analyze the effects of temperature, pressure, and material composition on the final product’s yield and quality. By analyzing these variables simultaneously, the researchers identified optimal conditions that balanced yield and quality, which would not have been possible by examining each response variable in isolation.

In a pharmaceutical development experiment, researchers used DOE combined with multivariate analysis to evaluate the effects of various drug formulation variables on efficacy, stability, and side effects. The multivariate approach allowed them to identify formulations that maximized efficacy while minimizing adverse effects, demonstrating the power of integrating these techniques in complex experimental settings.

Advantages of Multivariate Techniques in DOE

Image Source: Freepik

Integrating multivariate techniques in experiment design offers several advantages, including enhanced understanding and optimization of complex systems and processes.

Enhanced Understanding of Complex Interactions: Multivariate analysis enables the simultaneous examination of multiple factors and their interactions. This comprehensive view can reveal complex interactions that might be overlooked in univariate analyses, providing a deeper understanding of the system under study.

Improved Process Optimization and Quality Control

By considering multiple response variables simultaneously, multivariate techniques allow for optimizing processes to achieve multiple objectives, such as maximizing output while maintaining quality standards. This holistic approach can lead to more efficient and effective process improvements.

Ability to Handle High-Dimensional Data

Multivariate analysis is valuable in experiments with many variables. Techniques such as PCA can reduce dimensionality, simplifying the analysis without significant information loss. This makes it possible to analyze complex datasets that would be intractable with traditional univariate or bivariate methods.

Facilitates Decision Making

The comprehensive insights multivariate analysis supports more informed decision-making. By understanding how multiple variables interact to affect outcomes, decision-makers can devise strategies that are more likely to achieve desired results.

Increases Experimental Efficiency

Integrating multivariate analysis with DOE can reduce the need for extensive univariate testing by identifying the most critical variables and their interactions early in the research process. This efficient use of resources can accelerate the experimental timeline and reduce costs.

Practical Applications of Multivariate DOE

Image Source: Freepik

The application of multivariate Design of Experiments (DOE) spans various industries, showcasing its versatility and effectiveness in optimizing processes and enhancing product quality. By examining practical applications, we can appreciate the real-world impact of this approach.

Manufacturing Industry

Multivariate DOE plays a pivotal role in process optimization and quality improvement in manufacturing. By analyzing multiple variables simultaneously, manufacturers can identify the optimal settings for machinery and processes to maximize output and minimize defects. For instance, in the automotive industry, multivariate DOE is used to assess the influence of material properties, design parameters, and manufacturing processes on the durability and performance of components. This holistic approach enables manufacturers to balance efficiency, cost, and quality, leading to more reliable products and competitive advantages in the market.

Pharmaceuticals

The pharmaceutical sector relies on multivariate DOE for drug formulation and development processes. This method helps understand how different formulation variables affect drug stability, efficacy, and side effects. Researchers can optimize formulations to meet stringent regulatory standards while ensuring patient safety and therapeutic effectiveness by considering multiple response variables, such as release rate and bioavailability.

Additionally, multivariate DOE aids in the scale-up process, ensuring that drugs can be manufactured commercially without compromising quality.

Agriculture

In agriculture, multivariate DOE optimizes crop yield and improves resistance to pests and diseases. By examining factors such as irrigation levels, fertilizer types, and planting densities, researchers can identify the best combinations to enhance crop performance under various environmental conditions. This approach not only increases agricultural productivity but also contributes to sustainable farming practices by minimizing the use of water and chemicals.

Food Industry

The food industry employs multivariate DOE to refine recipes, processing techniques, and packaging methods to enhance flavor, texture, and shelf life. By analyzing how different ingredients and processing temperatures interact, food scientists can develop products that meet consumer preferences while ensuring safety and nutritional value. This method is also valuable in scaling up production, ensuring that the quality and taste of the product remain consistent across large batches.

Environmental Engineering

In environmental engineering, multivariate DOE addresses complex environmental challenges like water treatment, air pollution control, and waste management. Engineers can design more effective and efficient systems for mitigating environmental impacts by exploring the interactions between various treatment components and operational parameters. This approach supports the development of sustainable technologies that can be implemented on a large scale to protect ecosystems and public health.

Software and Tools for Multivariate DOE

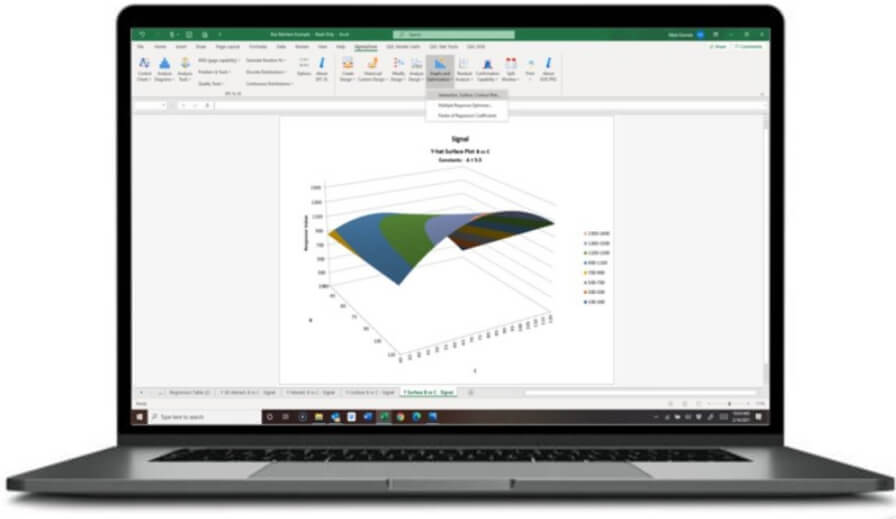

Air Academy Associates offers several software tools for multivariate analysis in the Design of Experiments (DOE), each with unique features tailored to different aspects of data analysis and process optimization:

- SPC XL: This tool is designed for statistical process control, helping users monitor and improve process performance over time.

- DOE PRO XL: Focused on designing and analyzing experiments, it simplifies the application of DOE principles for process optimization.

- Quantum XL is a comprehensive tool that integrates with Microsoft Excel and provides advanced capabilities for statistical analysis, including DOE.

- Simware Pro: Offers simulation capabilities, allowing users to model and analyze complex systems and processes to predict performance under various scenarios.

Tips for Selecting the Right Tool

When choosing the right software for multivariate DOE, consider the following tips:

- Assess Your Needs: Clearly define your objectives and the complexity of your experiments to match the software’s capabilities.

- Ease of Use: Choose software that aligns with your team’s expertise level. User-friendly interfaces can accelerate the learning curve.

- Integration and Compatibility: Ensure the software integrates well with other tools and systems you use, such as Excel for Quantum XL.

- Support and Resources: Look for software that offers robust support, tutorials, and resources to help you maximize its potential.

- Cost-Effectiveness: Consider the software’s cost relative to its features and value to your experimental analysis.

Conclusion

Incorporating multivariate analysis in the Design of Experiments elevates our comprehension and optimization of complex systems, offering profound insights into the multifaceted interactions within data. This approach empowers professionals to make informed decisions, streamline processes, and enhance efficiency. By embracing sophisticated analysis techniques and leveraging the right tools, we unlock the potential for significant advancements in various fields, pushing the boundaries of what can be achieved through informed experimentation.

Take your Design of Experiments skills to the next level by enrolling in our Operational Design of Experiments Course. This course offers in-depth training in DOE principles, equipping you with the expertise to conduct sophisticated analyses and achieve optimal process improvements. Join now and begin your journey towards mastering DOE.